1. YC-1500CS Full-cleaning Corrugated Paper Die-cutting Machine

YC-1500CS automatic leading edge paper die-cutting machine, manufactured with international advanced technology, is the key equipment in the corrugated cardboard packaging process. This machine uses high-strength gripper row, and the advanced open-grip gripper mechanism can adapt to various types of corrugated cardboard. The front and rear positioning and side positioning mechanisms ensure the die-cutting accuracy of the paper. The main drive of this machine adopts worm gear and worm and a specially designed crankshaft connecting rod mechanism, which is connected in the form of a bearing bush to reduce the movement gap and avoid the impact of the worm gear and worm. It is made of alloy copper with excellent abrasiveness and has a long service life. The machine adopts the domestic advanced ternary cam indexing mechanism, pressure regulating system, pneumatic locking plate, and pneumatic sampling. Overload protection device. Adopt imported high-precision chain drive, imported pneumatic clutch. The pneumatic locking mechanism can make the plate change and the pad plate more flexible and convenient. Programmable controller and man-machine interface, digital display of the machine's working speed, number of processed sheets, total running time, and machine fault display make troubleshooting very convenient. Realize automatic control and real-time monitoring of paper feeding, die-cutting, and paper delivery, and cooperate with safety devices in each part to make the operation safe and reliable. The die-cutting pressure can be adjusted separately before and after, and manual turning is convenient and labor-saving. Automatic paper delivery and neat paper loading make paper delivery convenient and tidy. The steel plate suspension function allows the steel plate to be pushed in and out easily.

2. The Local Introduction of The YC-1500CS Full-cleaning Corrugated Paper Die-cutting Machine

Front paper feeding section

▶ The uniquely designed leading edge feeding technology device adopts the non-stop down suction leading feeding method, and the large-capacity fan is equipped with frequency conversion adjustment, which relatively solves the problem of cardboard warping and makes the feeding smoother.

▶ The front paper stop blade can be adjusted up and down according to the thickness of the paper. The automatically adjusted side baffles can quickly adjust the width of the paper basically in place, and can also fine-tune the independent sitting position.

▶ The high-speed precision leading edge feeding system can stably convey various types and qualities of corrugated paper, with strong adaptability and effective protection of scratches and scratches on the printing surface. The variable frequency air volume adjustment and the special material feeding rubber roller can easily adapt to the feeding requirements of different corrugated paper from E tile to five layers, and ensure the smooth conveying of heavy and warped cardboard and the accurate positioning of the cardboard.

▶ The rear paper stop mechanism of the side partner paper device is all electrically adjusted, which improves the adjustment efficiency.

Lower suction paper feeding section

▶ Adopt down suction type non-stop feeding method.

▶ Pneumatic side push baffle pushes the paper stack in advance.

▶ The cardboard is fed into the platen roller by vacuum adsorption, which is not easy to scratch the printing surface.

Feeding table side positioning part

▶ The paper conveying adopts high-power servo drive, and is equipped with a unique curved motion trajectory to ensure that the paper is in place accurately.

▶ Phase adjustment PLC control is more precise and precise.

▶ There are one set of side positioning push gauges on the left and right sides. The selection of the reference plane is large to ensure the positioning accuracy of the side feeding of the paper.

▶ The front gauge and side gauge are wide-width design, which enables high-precision die-cutting as well as mounted paper.

▶ The front gauge has a fine adjustment device for the left and right jaws, and the gauge can be aligned simply by turning the handwheel.

▶ The unique upper and lower front gauge cooperates with the gripper mechanism to ensure that the warped paper can be transported smoothly and the die-cutting accuracy is guaranteed.

Die cutting

▶ Crankshaft linkage type high-precision plane movable die-cutting table.

▶ High-precision imported gripper row transmission chain. The precision of the machine is guaranteed. The whole machine is equipped with 8 gripper rows, and is equipped with 12 movable gripper sheets and supporting fixed dental pillows; the front and rear pre-positioning of the teeth rows are accurate to ensure accurate and consistent step distance positioning.

▶ Each paper detection sensor monitors the whole process of paper and reduces unnecessary paper waste.

▶ The central positioning system of the template makes the plate change simple and quick. The large-screen electronic fault display and speed display (color LCD) monitor the operation of the entire machine in time.

▶ Each part of the forced lubrication system adopts cooling circulation device with oil pressure display and oil cut-off alarm device.

▶ The main drive is mainly driven by imported belts and connecting rods, which reduces the impact of the main engine during movement and uses imported belts to ensure the service life and the timeliness and convenience of after-sales service.

▶ The high-quality high-torque cam divider drives the paper feeder row to make the operation more stable, reducing the phenomenon of loose plates in the process of die-cutting and cleaning; and is equipped with a high-torque overload protection system to protect the machine from being damaged when overloaded. The central positioning system adopted by the die-cutting board frame conforms to international standards, making it easier and faster to replace the blade. Save changeover time. When the tooth row needs to stay in the die-cutting part, the movable positioning is adopted to make the die-cutting positioning more accurate.

Torque Limiter, Intermittent Splitter

▶ Taiwan high-precision intermittent divider, long-term use can also ensure high positioning accuracy

▶ Taiwan torque limiter, with its sensitive limit protection performance, plays a very good role in protecting personal and mechanical safety against some man-made operation accidents.

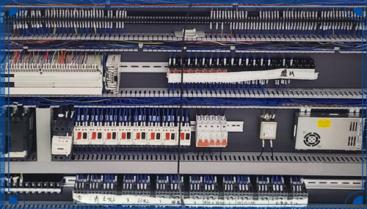

Electronic Control Department

▶ This machine adopts imported Schneider, Omron and other original components to improve the control quality.

▶ Using Schneider programmable PLC control system, the circuit control program is simple, and the maintenance is simple.

3. The Technical Parameter of The YC-1500CS Full-cleaning Corrugated Paper Die-cutting Machine

|

Max.Paper Size

|

1500x1200mm

|

|

Min.Paper Size

|

550x450mm

|

|

Max.Cutting Size

|

1490x1180mm

|

|

Max.Pressure

|

400T

|

|

Sheet Thickness

|

Cardboard):100-2000g/㎡ Corrugated:≤4mm

|

|

Conveying Paper Thickness

|

Cardboard 1.5-8mm

|

|

Blank size in mouth

|

9-17mm

|

|

Max.Cutting Speed

|

4500sheet/h

|

|

Total Power

|

18kw

|

|

Air Pressure/Traffic

|

0.55-0.7Mpa/>0.6m³/min

|

4. Main Components Configuration Details

|

No.

|

Name

|

Model and Specification

|

manufacturer

|

Remark

|

|

1

|

worm gear

|

ZQAL9-4

|

German alloy material

|

With scraping

|

|

2

|

crankshaft

|

40Cr

|

domestic

|

Induction hardening

|

|

3

|

worm

|

41Cr

|

domestic

|

tempering, high frequency

|

|

4

|

platform

|

QT50-5

|

domestic

|

resin sand casting

|

|

5

|

frame

|

Quick plate lock

|

domestic

|

45# steel quenched and tempered

|

|

6

|

steel plate

|

65Mn

|

Shanghai

|

Hardness: HRC45-50

|

|

7

|

gripper row

|

Aviation hard aluminum alloy

|

Hafei

|

|

|

8

|

tooth row chain

|

IWS

|

Germany

|

|

|

9

|

Intermittent mechanism

|

250

|

Taiwan

|

ternary cam

|

|

10

|

Pneumatic clutch

|

304-9

|

Italian Yuyi

|

|

|

11

|

Inverter

|

Toshiba

|

Japan

|

|

|

12

|

Programmable Controllers

|

|

Omron

|

|

|

13

|

HMI

|

Weilon

|

Taiwan

|

|

|

14

|

PLC

|

Omron

|

Japan

|

|

|

15

|

main motor

|

WEG

|

Taiwan

|

|

|

16

|

Bolt Track Bearings

|

IKO

|

Japan

|

|

|

17

|

The electromagnetic valve

|

AIRTAC

|

Taiwan

|

|

|

18

|

button

|

Schneider

|

France

|

|

|

19

|

relay

|

Omron

|

Japan

|

|

|

20

|

contactor

|

Schneider

|

France

|

|

|

21

|

Photoelectric switch

|

Omron

|

Japan

|

|

|

22

|

Limit switch

|

|

Taiwan Tiande

|

|

|

23

|

cylinder

|

Shenchi

|

Shanghai

|

|

|

24

|

front fiber

|

PANASONIC

|

Matsushita

|

|

|

25

|

slider

|

ZQCSN6-6-3

|

German Alloy

|

|

|

26

|

give paper

|

Specially designed high precision feeder head

|

domestic

|

|

|

27

|

Worm gear bearing

|

NSK

|

Japan

|

|

|

28

|

reducer

|

Shengbang

|

Taiwan

|

|

|

29

|

Rotary joint

|

SMC

|

Japan

|

|

Random Accessories

|

name

|

quantity

|

Remark

|

name

|

quantity

|

Remark

|

|

Flat-blade screwdriver

|

1

|

150

|

Allen key

|

1 set

|

|

|

Phillips screwdriver

|

1

|

150

|

socket wrench

|

1 set

|

1 set

|

|

adjustable wrench

|

1

|

300

|

rocker wrench

|

1

|

|

|

Steel handle

|

1

|

|

pressure oil gun

|

1

|

|

|

Hammer

|

1

|

|

toolbox

|

1

|

|

|

oil can

|

1

|

|

|

|

|

Add random accessories and wearing spare parts

|

No.

|

name

|

quantity

|

|

1

|

plate frame

|

1 set

|

|

2

|

steel plate

|

1 piece

|

|

3

|

tooth row

|

1 set

|

|

4

|

fixed teeth

|

10

|

|

5

|

active tooth

|

10

|

|

6

|

help reed

|

10

|

|

7

|

nozzle rubber

|

16 (2 sets of 1 each)

|

|

8

|

paper split reed

|

12 (2 sets of 1 thin and thick)

|

|

9

|

electrical straps

|

5 pieces each

|

|

10

|

Spare dome head screw M6X8

|

8

|

|

11

|

Expansion bolt M8

|

2 pieces

|

|

12

|

Throat hoop∮30

|

8

|

|

13

|

paper feed board

|

1 set

|

|

14

|

Hair wheel (hard hair)

|

4

|

|

15

|

paper separation brush

|

2

|

|

16

|

Pressed cardboard

|

1 set

|

|

17

|

Torsion spring (A0714A.A0714B)∮2.5

|

7 pieces each

|

|

18

|

Rubber pad 200×200

|

6 pieces

|

|

19

|

Push gauge LG31.LG32

|

1 each

|

|

20

|

Paper stop C0637B

|

2 pieces

|

|

21

|

Elastic self-adhesive strip

|

1 plate

|

|

22

|

Rainproof silk machine cover

|

1

|

The Service of Tangshan Yuancheng Printing Machinery Co., Ltd.

The local agent service provider is responsible for the after-sales service of overseas business, and the product production cycle is 1 to 3 months.

After-sales service content:

1). The equipment provided by our company is guaranteed for one year (excluding consumables). During the warranty period, the local agent service provider is responsible for free maintenance for problems caused by the equipment itself.

2). Our company implements a whole-process tracking management system from the factory to the effective service life of the product. Establish product technical file management system and after-sales service guarantee system.

3). The company uses the "Yuancheng" brand as a guarantee to ensure the company's commitment to quality assurance to users. This guarantee has legal effect and will not be invalidated due to changes in the company's development.

Note: Due to the continuous upgrading of products, such as changes in technical parameters, equipment configuration, and appearance, the actual product shall prevail.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা

বাংলা  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  Gaeilge

Gaeilge  عربى

عربى  Indonesia

Indonesia  norsk

norsk  اردو

اردو  čeština

čeština  Ελληνικά

Ελληνικά  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Македонски

Македонски  Lietuvos

Lietuvos  Română

Română  Српски

Српски  icelandic

icelandic  Shqiptar

Shqiptar  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  Точик

Точик  O'zbek

O'zbek  Lëtzebuergesch

Lëtzebuergesch