Features

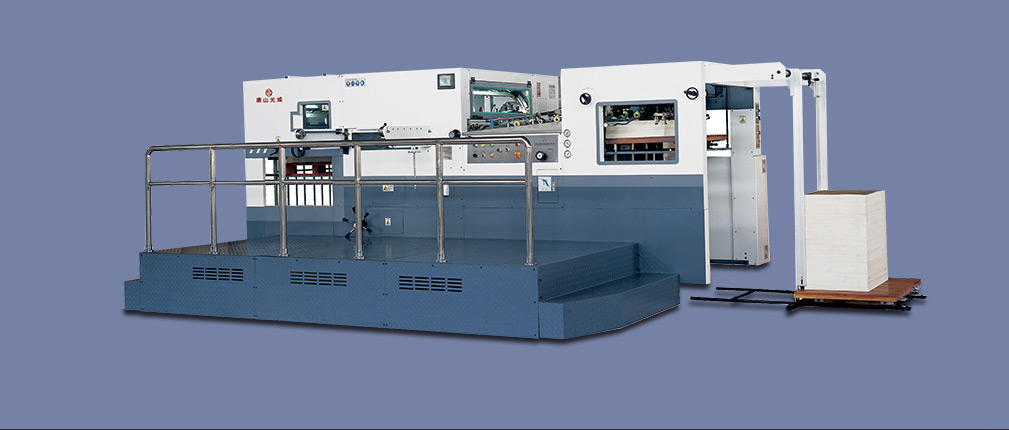

FeaturesThe 1060A/1060C automatic die cutting and creasing machine is pivotal equipment,which is designed for die cutting,creasing and cold embossing paper products such as paper cassettes,box board containers,papertrademarks,etc.Unique drive gears are adopted such as high-precision indexing mechanism, pneumatic Closed up,pneumatic Clutch,overpower protection,manual compression relief etc.,to ensure stable and high speed runnmg of the machine. This machine is equipped with practical and reliable mechanisms such as pre- stack device,secondary delivery mechanisms,manual sampling,etc.,which ensure the excellent performance of the machine.Electrical,components and driving elements of internationally known brands are adopted to ensure die cutting precision and reliability of running.Also man- machine interface is used to monitor the machine state to display running status, trouble location,troubleshooting and relevant help information to fully actualize man-machine com

Technical Parameters

Technical Parameters| Model | 1060A/1060C |

| Max.SheetSize | 1070x790mm |

| Max.DieCuttingSize | 1060x780mm |

| DieCuttingPrecision | ±0.1mm |

| CardboardSpecification | 100-2000g/m2 |

| Max.Height of FeedingPile | 1380mm |

| Max.Height of Delivery Plie | 1100mm |

| Total Weight | 16.6T/17T |

| Min.Sheet Size | 1450x360mm |

| Min.Front Margin | 5mm |

| Max.Die Cutting Pressure | 250T |

| Corrugated Paper | ≤4mm |

| Max.Die Cutting Speed | 7000/8000sheet/h |

| Total Power | 16/18kw |

| Overall Size(LxWxH) | 6370x3780x2060mm |

Introduction

Introduction-

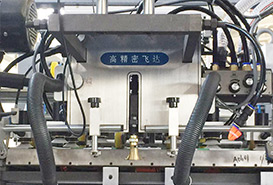

Feeder

FeederUsing four European technology taking four paperboard, corrugated paper amphibious suction head. Suction can cooperate with paperThe deformation condition of non-stop adjust the Angle of all kinds of paper, make the paper more stable. A simple adjustment The use of the function and precision control function. Thickness to two or morethings, smooth paper accurately.

-

Die-cutting part

Die-cutting partThe safety of the die cutting plate and knife template design, move easily, the design of the rotary device to make plate Adjustable version faster more convenient. Pneumatic lock version of the device makes the space/fixed firmer, more accurate,Save time.

-

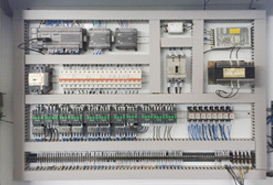

Electric Control

Electric ControlThe machine adopts Japanese omron PLC program control, frequency conversion governor. All kinds of electrical components,Detection switch adopts companies such as Japan, France, Taiwan famous brand product. Operational control precision,Stable performance.

-

Side Lay

Side LaySpecially designed side gauge structure integrating push-pull, just arbitrarily according to different products Choose adjustment, don't need to change parts, push and pull of swaps can be realized. When usingSmall displacement gauge drawing process, the paper, to not scratch paper edge, very suitable for high speed feed.

-

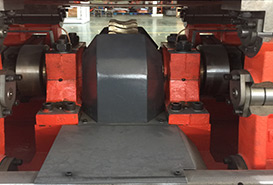

Crank Shaft

Crank ShaftWorm gear materials with German alloy copper, precision machine tool processing, high precision and special wear-resisting.Worm shaft with chrome steel high frequency quenching treatment, long service life. Swinging rod size increase, the pendulum Bold rod shaft, so the die cutting pressure, wear-resisting and durable.

-

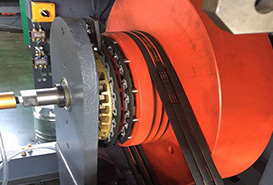

Pneumatic Clutch

Pneumatic ClutchImported pneumatic clutch, long life, low noise, braking more smoothly, clutch is rapid,Momentum is big, meet European export standards. Brazil WEG motor pen domestic energy-saving one-third.

-

Paper transport department

Paper transport departmentImport feed belt with high wear-resisting paper roller pressure, the handwheel, easy to adjust the lugs and wool wheel Pressure to change with the pressure of the belt, to ensure smooth paper sent to the former provisions of a part. Reduce downtime in the work.

-

Man-machine Interface

Man-machine InterfaceThe machine adopts imported high resolution man-machine communi cation interface, to the running state of the machine The real-time dynamic monitoring, according to the machine adjustment and troubleshooting for convenient and quick, safe and reliable.